Trustwell Honored as Multiple Stevie® Award Winner in 2025 American Business Awards®

Event Recap: AIDC 101 Workshop – April 16, 2025

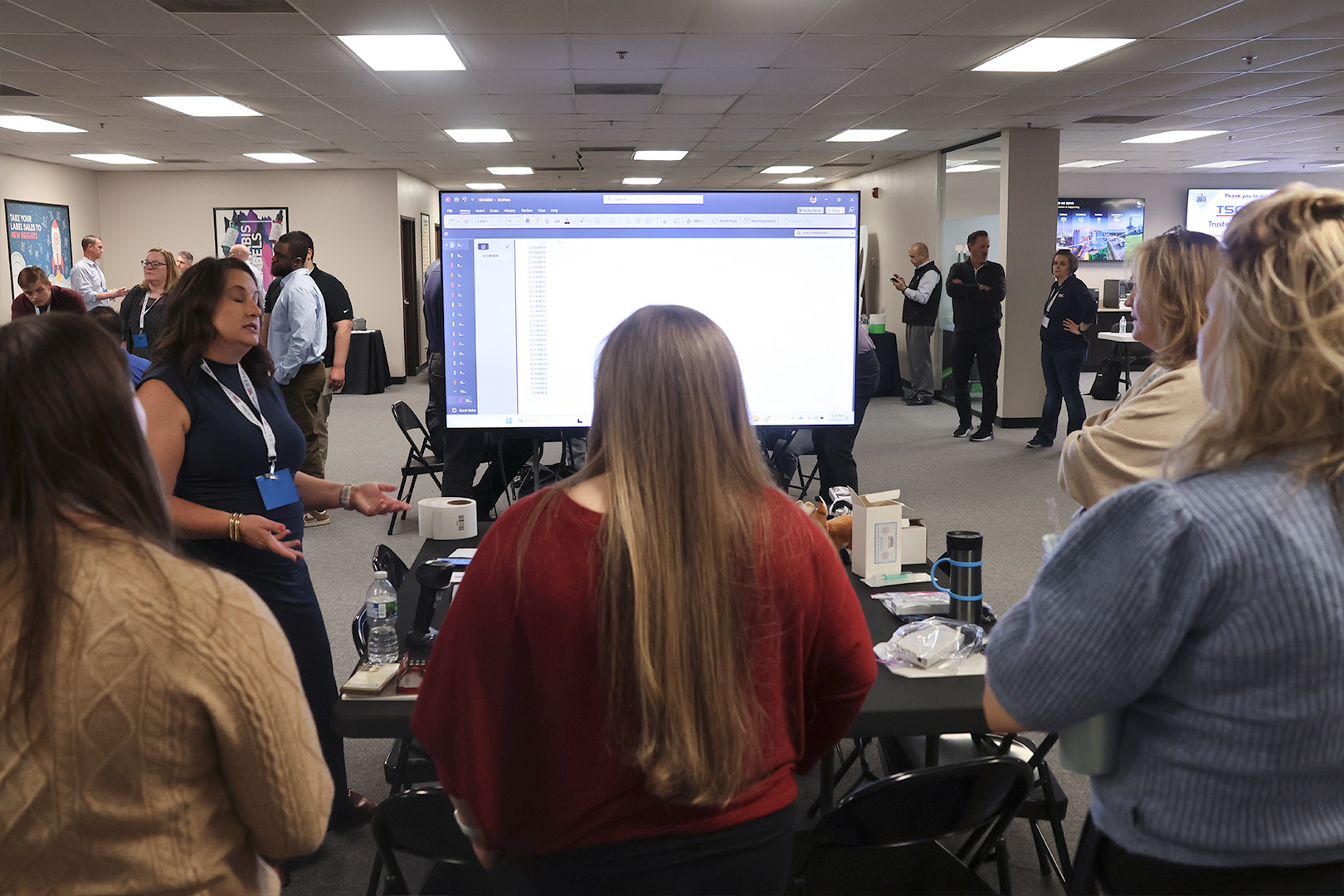

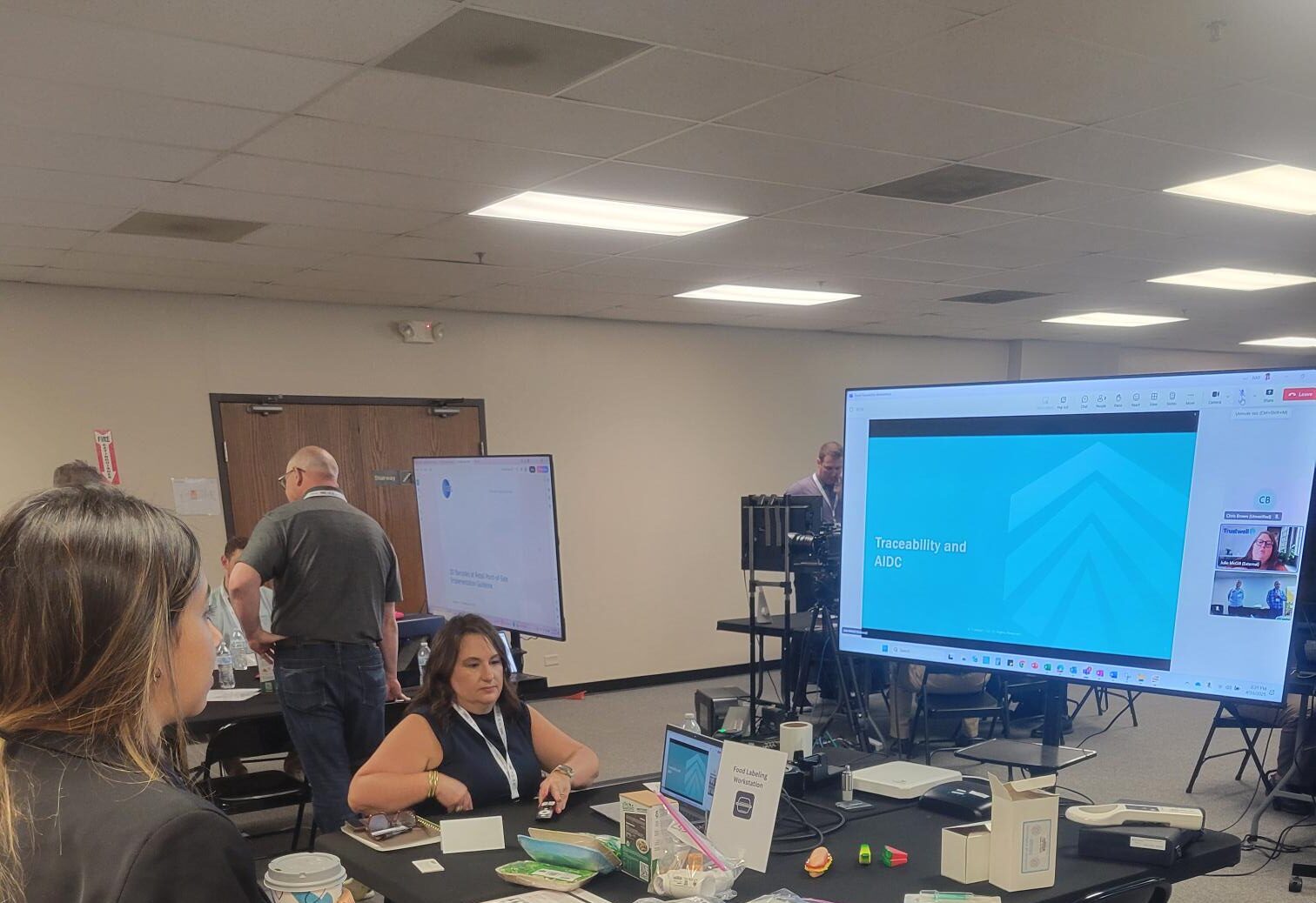

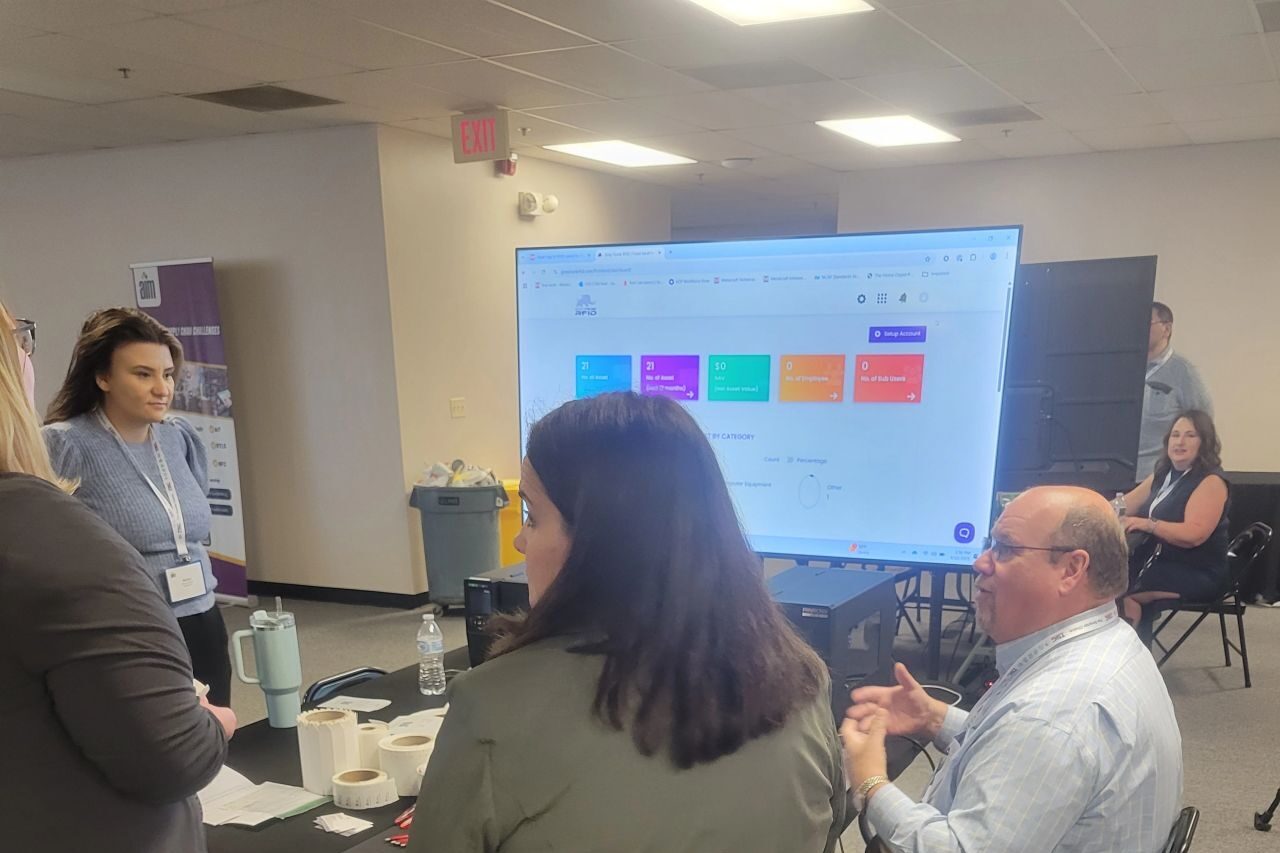

On April 16, AIM hosted its inaugural AIDC 101 Workshop at the TSC facility in the Chicago area. This one-day, immersive experience was designed to introduce attendees to the foundational elements of automatic identification and data capture (AIDC) technologies. With over 20 participants in attendance, the workshop provided an ideal setting for both learning and networking, combining educational sessions with hands-on demonstrations from industry sponsors.

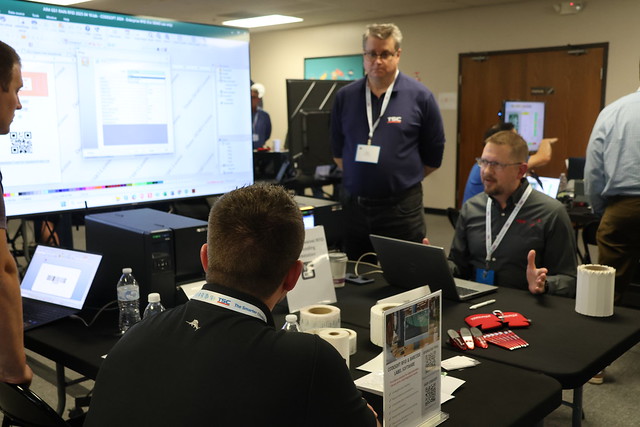

The day began with open access to sponsor tables, where attendees had the chance to explore demos and connect with leading solution providers from SpotSee, SICK, Zebra Technologies, Seagull, TEKLYNX and Metalcraft. They also got to see AsReader and FEIG’s handheld equipment. The formal program launched soon after and featured four structured sessions that guided participants through the landscape of AIDC:

What is AIDC?

Led by Amy Awe of NXP, this session introduced the core concepts of AIDC, including its history, purpose, and key technologies such as barcodes, RFID, NFC, and digital watermarks. Attendees also gained insight into commonly used terminology and symbologies across industries.

Equipment & Applications

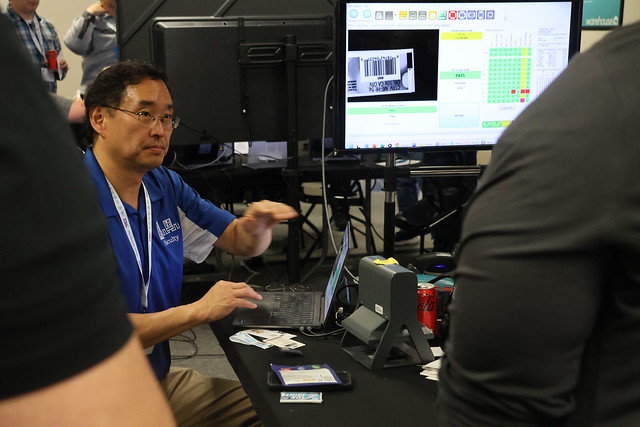

This session covered by Chris Brown from TSC discussed the essential tools of the trade—from barcode scanners and RFID readers to encoders, printers, and verification devices. Attendees learned how these components work together to enable data capture across various environments.

The Current AIDC Landscape

A high-level overview of the market from the University of Memphis’ Kevin Berisso; this session examined the structure of the AIDC industry, key players, trends, and AIM’s role in shaping innovation and standards adoption.

AIDC Standards & Governing Bodies

Attendees were introduced to the various national and international organizations that develop and maintain standards for AIDC technologies, ensuring global interoperability and trust. This session was hosted by Michael Allen of AIM.

Following the morning sessions, attendees participated in two rounds of hands-on breakout demonstrations, which brought the technologies and concepts to life in real-world scenarios. These included eight interactive stations, split between the “Generating Sample Solutions” session and “AIDC in Practice” session:

Generating Sample Solutions

Barcode Creating

Attendees created barcodes using BarTender and Codesoft software, printing real labels and learning about proper design and formatting.

Barcode Scanning

Participants tested both handheld and fixed barcode scanners, exploring how different scanning setups work in various environments.

RFID Tag Encoding

Using dedicated printers and software, attendees encoded RFID labels and understood tag selection based on use cases.

RFID Reading

Hands-on exercises included scanning RFID tags with multiple reader types to understand range, tag orientation, and data read rates.

AIDC in Practice

Retail Scanning

Participants experienced UPC barcode scanning and learned about GS1’s Sunrise 2027 initiative.

Food Labeling & Traceability

This station explored how AIDC supports food safety and transparency across supply chains.

Logistics Labeling

Participants experienced UPC barcode scanning and learned about GS1’s Sunrise 2027 initiative.

Inventory Count

Attendees used software platforms such as GreyTrunk to perform sample inventory operations.

The day concluded with an optional plant tour of TSC Printronix Auto ID, followed by an open Q&A, networking break, and certificate distribution to all attendees for completing the class.

The response from attendees was overwhelmingly positive. As one participant, Stephanie Podgor, Business Development & Marketing Specialist at TEGO, shared:

The AIDC 101 Workshop was such a great experience—educational, engaging, and really well-executed. The speakers did a fantastic job laying the groundwork for those of us newer to the AIDC space, and the hands-on demos made the concepts click in a real-world way. The day flowed smoothly, the group size was just right (about 30 people), and it was easy to connect, ask questions, and have meaningful conversations. It was my first AIM event, and definitely won’t be my last!

AIM extends its gratitude to all sponsors, speakers, and attendees who helped make this event a resounding success. The AIDC 101 Workshop demonstrated the value of combining education with application—and highlighted how AIM continues to support the growth and adoption of AIDC technologies. Be on the lookout for future educational opportunities like this one!

Global Chapter Highlights: AIM’s Expanding Impact Across Regions

Over the past year, AIM chapters around the world have made impressive strides in advancing the adoption and impact of Automatic Identification and Data Capture (AIDC) technologies. With a renewed focus on education, outreach, and collaboration, these regional efforts are not only strengthening local engagement but also shaping global best practices in the AIDC community. Below are some of our chapters latest initiatives, which were discussed at the AIM Summit event:

In India, AIM India has experienced transformative growth. A strong digital presence was established through the launch of a website, a LinkedIn Company page, an X account, and a dedicated YouTube channel. These platforms have become hubs of activity, helping to expand awareness and promote the value of AIDC technologies to a broader audience. This visibility is backed by an ambitious webinar program that kicked off in May 2024 with the organization’s inaugural event, The Future of AIDC Technologies. The session featured three expert presentations that offered forward-looking insights into the evolution of AIDC. In August, AIM India hosted RFID for Supply Chain Traceability and Inventory Count, a deep dive into the practical applications of RFID in logistics. October brought the third installment, Positive Patient ID as a Cornerstone of Patient Safety, which explored the life-saving benefits of AIDC in healthcare environments. These sessions have not only informed attendees but have sparked genuine excitement within the community. AIM India also participated in the North Zone Meet organized by the AIDC Technologies Association of India at Crowne Plaza in Okhla, furthering connections within the national ecosystem. Looking ahead, AIM India plans to launch a regular newsletter, expand collaborations with like-minded associations, continue its webinar series, grow its membership, engage in more conferences, and produce additional educational content for YouTube and beyond.

Meanwhile, in Europe, AIM AIM-D e.V. is preparing for a full slate of events and expert forums in 2025. The Spring Meeting, hosted by Think WIOT Group, will be held in Lüneburg from May 7–9, followed by the Autumn Meeting in Waldkirch from November 5–7, hosted by SICK. AIM Germany also has a strong presence at industry trade shows. LogiMAT 2025 in Stuttgart is already sold out with 12 partners committed to the AIM Booth and continued programming at the popular AIM-ident Experts Forum and Tracking & Tracing Theater. Additional participation is planned for transportation logistics 2025 in Munich and the #WIOT25 conference in Wiesbaden, where AIM will present lectures and host expert panels. Planning for LogiMAT 2026 is already underway, with booth reservations now open.

In terms of technical initiatives, AIM – D e.V. supports several active and emerging expert groups. The RFID & Sensors group continues its work on market development and technical refinement, with an updated white paper expected in Q4 2024. Optical Readable Media (ORM) efforts are ongoing, including work on standards such as IEC 61406 and verifier conformance for DPM. Marketing and regulatory teams are focused on market research, frequency harmonization, and critical EU regulations such as the Radio Equipment Directive and Cyber Resilience Act. Projects like the integration of AIDC in recycling systems and discussions on digital product passports reflect the chapter’s commitment to sustainability. Although some expert groups, such as AutoID & Security and RTLS, are currently paused due to leadership transitions, others like System Integration remain highly active. The RFID & IO-Link joint group launched in 2023 continues to hold regular meetings, with the next scheduled for April 8, 2025.

AIM Denmark‘s shared the latest developments with their international network. Their recent seminar at føtexGo—the first cashier-free store in Denmark—offered valuable insights into the future of retail and seamless shopping experiences. At their General Assembly, members re-elected the board, reinforcing our shared commitment to advancing the industry.

Now, all eyes are on RFID & IoT in the Nordics 2025, happening in Copenhagen on June 12th under the theme “Data as the Digital Heartbeat – Transparency and Value Creation in Modern Value Chains.” With the event fast approaching, AIM Denmark invites professionals and organizations across the AIM Global community and beyond to join them — whether as attendees eager for fresh perspectives or as sponsors looking to engage with key players in the Nordic and European markets.

Learn more and register for the conference at www.aidcdkconference.org or reach out by mail to conference@aidcdk.org

AIM Asia has also made noteworthy progress, forming a new EMC & RF Workgroup aimed at addressing evolving communications infrastructure challenges and ensuring environmental compatibility. In addition, the AIM Asia Education Arm has been established as a nonprofit, collaborative platform designed to bridge STEM learning with industry innovation. This educational initiative offers open-source courses, industry-aligned certifications, and career pathways to build a sustainable talent pipeline for the future. Plans are already underway for a 2025 seminar series under the theme “Building Synergies Across AIM Member Companies,” which will highlight case studies, branding strategies, and cross-border opportunities through the Asia-Pacific Economic Cooperation (APEC). AIM Asia’s regional footprint includes engagement with stakeholders in Hong Kong, China, Singapore, Thailand, Malaysia, Indonesia, Japan, and Korea.

In North America, AIM North America is concentrating efforts through dedicated work groups focused on food safety, cannabis compliance, and unique device identification (UDI). The food group is conducting a survey to assess service practices, while the UDI group is working to resolve barcode decoding challenges within healthcare. Meanwhile, the cannabis workgroup is developing an educational podcast and webinar series to support this emerging industry’s labeling and tracking needs.

AIM Russia has played a pivotal role in advancing the national traceability system. In close collaboration with GS1 Russia, it provides expert guidance on the implementation of AIDC technologies such as UHF RFID and DataMatrix across a wide array of product categories, reinforcing its leadership in the field. AIM Russia is also deeply involved in a national initiative aimed at leveraging AIDC for product identification, traceability, and logistics optimization. The project’s scope continues to expand, now covering both food and non-food items. To support this effort, AIM Russia regularly delivers training and consulting services to participants, underscoring its commitment to industry development.

AIM Europe has sustained strong membership growth into the summer and is actively preparing for participation in LogiMat. The organization remains highly engaged in standardization initiatives with CEN and ETSI, working to promote the adoption and development of AIDC technologies across Europe.

AIM Korea has been jointly operated by KAIIA (Korea Automatic Identification Industry Association). Their focus lies in technological innovation and workforce development, particularly in auto ID applications utilizing barcodes, RFID, and IoT.

AIM China has contributed significantly to the Prepackaged Food Digital Label Platform, supporting over 70 food companies in transitioning from traditional to digital labels. This shift has enhanced both consumer experience and industry efficiency. AIM China continues to foster knowledge-sharing and capacity-building within the sector.

Across all regions, AIM chapters are demonstrating leadership through innovation, collaboration, and education. Their collective work is driving the future of AIDC and reinforcing the global value of standards-based identification technologies. Stay tuned for more updates as we continue to grow and connect the AIDC community worldwide

If you would like to gain more insights into AIM’s global chapters, contact Michael Allen at mike@aimglobal.org.

ID Integration CEO to Present on Passive RFID Laboratory Asset Tracking at RFID Journal LIVE! 2025

[Mukilteo, WA] – April 24, 2025 – ID Integration, Inc. is proud to announce that President & CEO Gary Moe will present a featured session at RFID Journal LIVE! 2025, held May 6–8 at the Paris Hotel and Convention Center in Las Vegas, Nevada. Moe will spotlight how passive RFID technology is revolutionizing laboratory asset management through a groundbreaking platform known as IDAS (Integrated Digital Asset System).

In his session titled “FDA IDAS RFID Laboratory Asset Tracking Solution,” Moe will explore how IDAS simplifies the tracking and management of critical laboratory resources—including chemicals, supplies, equipment, and samples—while improving compliance, traceability, and operational efficiency.

Session Date: Tuesday, May 6, 2025

Time: 11:55 AM – 12:35 p.m. PST

Location: Paris Hotel, Las Vegas | RFID Journal LIVE! 2025

Designed to support laboratories operating in high-stakes environments, IDAS integrates passive RFID with electronic lab notebooks (ELNs) to streamline ordering, receiving, locating, and reporting on assets in real-time. It provides a single, unified system that replaces manual tracking and barcode-only processes with automated visibility, improving collaboration across teams and reducing administrative burdens.

“IDAS represents a leap forward for digital inventory control,” said Gary Moe. “We’re seeing the power of RFID to transform how labs manage sensitive materials. This session will provide a look into the real-world benefits of implementing passive RFID for smarter, safer operations.”

Attendees will gain insight into:

- Passive RFID applications for real-time lab inventory tracking

- Improving sample integrity, compliance, and expiration management

- Reducing waste and over-ordering through smarter visibility

- How IDAS supports resource sharing across research teams

Moe’s presentation is part of the DOGE READY track at RFID Journal LIVE!—focused on Digital Optimization in Government & Enterprise—and reflects ID Integration’s growing leadership in applying RFID to modernize laboratory, manufacturing, and healthcare environments.

To learn more about the event or register to attend, visit: https://rfidjournallive.com

For more on ID Integration’s RFID expertise in laboratory and manufacturing settings, read our newest blog post, “Discover How to Be DOGE Ready with Laboratory Asset Management at RFID Journal LIVE!”

For more information about ID Integration’s automation solutions for laboratories, visit ID-Integration.com or contact Gary Moe: (425) 438-2533 or gmoe@id-integration.com.

###

About ID Integration, Inc.

ID Integration, Inc. is a pioneer in automated data capture technologies and integration solutions. For 25 years, ID Integration has been delivering innovative identification technology solutions to diverse industries, including government, military, aerospace, industrial, healthcare, and more. Their track record of enhancing productivity, ensuring accuracy, and reducing costs has made them a trusted partner for organizations seeking cutting-edge solutions.

Metalcraft Launches Global Universal RFID Tag for Seamless Worldwide Tracking

MASON CITY, IA – April 21, 2025 – Metalcraft, a leading manufacturer of custom identification solutions, is proud to announce the release of its latest innovation: the Global Universal RFID Tag. This powerful new product offers seamless performance across both FCC and EU frequency bands, making it the ideal solution for companies with global tracking needs.

The Global Universal RFID Tag is the newest addition to Metalcraft’s long-standing Universal RFID product line, which spans more than 15 years of pioneering RFID solutions for diverse industries. Engineered for global compatibility and designed to read up to 15 feet (4.57 meters) on metal surfaces, the Global Universal Tag ensures consistent, high-performance tracking — wherever your assets go.

“As businesses expand globally, they need RFID solutions that deliver consistent performance across regions,” said Kyle Bermel, CEO of Metalcraft. “The Global Universal RFID Tag eliminates the complexity of using different tags for different markets, making global asset tracking simpler and more efficient.”

Available in both preprinted and on-site printable versions, the Global Universal RFID Tag adapts to any workflow. For businesses looking to make a strong visual impact, the preprinted version supports full-color, four-color process printing, offering vibrant logo customization.

The Global Universal RFID Tag is available now. Metalcraft is currently offering free samples for testing. To request yours, contact Metalcraft at metalcraft@idplate.com, call 800-437-5283, or reach out to 641-423-9460.

A Guide to Ensure Measuring Devices are Accurately Assessing Performance and Quality According to Industry Standards

Checkpoint Systems deploys RFID technology at Champagne Charles Heidsieck

Exploring the Future of Supply Chains at ProMat 2025: A Recap from AIM

This week, I had the incredible opportunity to attend ProMat 2025 at McCormick Place in Chicago, where manufacturing and supply chain professionals from around the world gathered to explore the latest trends, technologies, and innovations shaping the future of the industry. As a representative of AIM, it was exciting to see firsthand how automation, robotics, and AIDC technologies are converging to drive greater efficiency, accuracy, and visibility across supply chains.

Connecting with AIM Members

One of the highlights of my visit was meeting with many of our AIM members who were exhibiting at the show, including:

- AsReader

- Avery Dennison

- Camcode

- COGNEX

- DecisionPoint Technologies

- HID Global

- Honeywell

- Levata

- Loftware

- Lyngsoe Systems

- Metalcraft

- Peak Technologies

- RFID KNOW

- SATO

- Seagull

- SICK

- TSC

- Zebra Technologies

It was great to catch up with these industry leaders and see the latest advancements in RFID, barcode technology, and track-and-trace solutions. Many of our members are beginning to integrate robotics, more advanced OCR and even machine learning into their offerings; creating more seamless, intelligent supply chain solutions. This growing synergy between AIDC and robotics is a clear indicator of where the industry is headed—toward greater automation, real-time data insights, and enhanced operational efficiency.

With over 1,100 solution providers showcasing cutting-edge technologies, ProMat 2025 was a hub of inspiration. From RFID solutions improving real-time asset tracking to AI-powered barcode verification systems enhancing accuracy in distribution centers, the event underscored the rapid evolution of automation and data-driven decision-making in supply chain management. Beyond the exhibit floor, keynotes and seminars provided insights into emerging trends such as digital twins, AI-driven supply chain optimization, and the role of AIDC in sustainability efforts. These discussions reinforced the importance of data accuracy and interoperability, areas where AIM and its members continue to drive progress through standards and innovation.

I also wanted to send a thank you to DecisionPoint Technologies for hosting a fantastic post-show networking event on Monday evening. It was a great opportunity to connect with industry peers, share insights, and discuss the exciting developments we saw throughout the day. Events like these are invaluable for strengthening relationships and fostering collaboration among supply chain leaders, and it was great to see several of our members at this event collaborating and networking.

As ProMat 2025 comes to a close, one thing is clear: the future of AIDC, automation, and robotics is more interconnected than ever. AIM remains committed to supporting our members and the broader industry as we navigate these exciting advancements.

If you attended ProMat and want to continue the conversation about how AIM can support your business, feel free to reach out. We look forward to continuing being a resource to drive the industry forward.

Metalcraft Becomes 100% Employee-Owned, Strengthening Commitment to Member-Owner Focus

MASON CITY, IOWA – [February 18, 2025] – Metalcraft, a leading manufacturer of barcode and RFID identification products, is proud to announce that it is now 100% employee-owned. The company has been an Employee Stock Ownership Plan (ESOP) organization since 2006 and has now transitioned to full employee ownership.

“Becoming 100% ESOP is really an extension of our core value, which is member-owner focus,” said Metalcraft CEO Kyle Bermel. “It also ensures we will stay locally owned and private for years to come.”

This milestone comes as Metalcraft celebrates its 75th anniversary, marking decades of innovation and customer-focused service. As a fully employee-owned company, Metalcraft continues to provide high-quality identification solutions to customers worldwide, leveraging barcode and RFID technology.

For more information about Metalcraft and its identification solutions, visit www.idplate.com.

About Metalcraft, Inc.

Founded in 1950, Metalcraft is a leading provider of customized identification solutions, including RFID tags, barcode labels, and asset tracking software. The company is headquartered in Mason City, Iowa, and serves a wide range of industries with innovative identification products.

Media Contact:

Julia Deets

VP Marketing & CX

Metalcraft

juliad@idplate.com

641-423-9460